Kiyoshi Mantis Knives

Branding & Product Design Development

This is placed here as well as the Merlin's Armoury section of this portfolio as it started as a Product Design project during my Industrial Design degree at Brunel University, for a multi purpose kitchen knife concept and design before becomming a LARP weapon due to the potential for the knives to be weaponised. You cvan see the design process here.

This was one of those if you can’t beat them join them projects. Not part of Merlin’s Armoury this began and for the most part was part of a university project to develop a high end branded kitchen product. The brand was developed as a group assignment, then we broke off to develop a product to fit the brand.

Top of the range kitchen knife brands like Global and Wüsthof. These were forged not stamped out blades and some were Damascus folded steel, similar to Japanese Samuri katana blades with different metals folded sand welded together to combine hardness and toughness.

Not being able to speak to professional chefs I decided to go for a combination of researching and encompassing (In terms of design as nowhere near trained in advanced Damascus and Japanese folded steel blade craftsmanship.) folded steel technology and craftsmanship in my designs, with the kinds of products seen in infomercials for multi-use kitchen products.

Sketch Development

Product Design Specifications

- Feature an ergonomically designed comfortable grip / hilt.

(Indented at the ends and rounded to fit palm in the middle. This was based on experiments gripping Plastacine) - Cut through dense vegetables like swede with ease with pressure on top.

(Handle on top, dence curved wide blade under. Top left below)) - Slice through the softest fish using fluted indents like seen on sushi and salmon knives.

(Very thin sharp hard fluted curved blade) - The ability to chop vegetables fast.

(Thining cuved blade under that is well balanced) - Pierce large meat or melon.

(Sharp point and strong blade) - Hack through coconuts.

(Attach a handle over the blade pointed end, so is can be brought down hard with a heavey tough end in the back like a cleaver or machetti. Mid right below) - Carry out delicate fruit carving as seen above in the mood board.

(When held upside down and backwards there is a scalple blade holder for fine work. Bottom centre below) - Crush nuts or similar.

(Spiked hammer on rear. Bottom Right) - The ability to hold food items with a second knife unit to keep fingers clear.

(The rear spiked curve. Bottom left below)

You can see some of this development in the sketches and Proving Principle Prototype (PPP) development below in yellow Sikablock Polyurethane (PU) modelling board making foam.

Proving Principle Prototyping PPP

Safety Issue Problem Solving

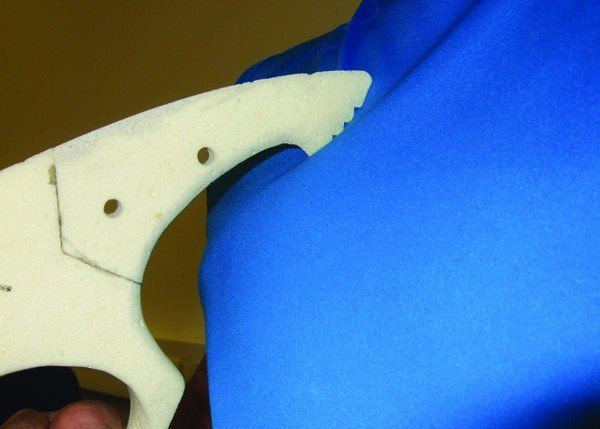

A simple solution which added to the design was to incorporate a serrated barb on the end. This would mean a lightly curved flattish blunt end impacts the body if the chef is not careful unlikely to pierce clothing or do any real damage if it did.

Kiyoshi Chef Knife Evaluation From Multi - Use Kitchen knife to LARP Weapon

- The fact that the system was scarily effective as a hand to hand weapon system meant that it would not be responsible to sell in places that those with sinister intent would have easy access to them.

- The fact that only become known well into the project was that professionals prefer single use specialist top end tools and knives as more effective for that one use and also to prevent food cross contamination.

- The to the weapon nature the lecturers ordered than no realistic prototypes could be made flat and thin from metal or similar and certainly not carried around on campus which hampered the assignment.

When held backwards much like the forearms of a praying mantis, the knives as a pair could be drawn from a back pair of sheathes in such a manner several surround people could be lethally sliced open as the knives are drawn.

The forms are perfect for short ranged, flowing, very fast swinging circular motions. Very ergonomic.

As well as slashing they are ideal like praying mantis in just the return stoke for:

- Hooking.

- Bladed punching much like punching axe head into someone.

- Back handed stabbing in a curved motion.

- Whilst the original point ends would have a lot of penetrating power the barbed end would rip apart a human’s insides and them rip them out as pulled from a body disembowelling them.

- The curved blade making it easier to pull back out of someone in a curved motion.

- The curved blade when slashing in an arc also increases the cutting ability much like the curve on a Samurai katana blade.

- The intended material hard & tough laminated and folded damascus steel popular in Japanese blade weapons would also be exceptionally hard & sharp.

- The flutes (Dents) would be effective in allowing the blade to slice through people without sticking as it would soft fish.

- Any knife in the hand of someone with sinister intentions is lethal as seen by the current knife crime epidemic. These knives in the hands of someone with any kind of martial arts ability should in theory be far more effective against many people at one. The kind of item seen in the hands of super heroes or villains.

- In particular they could be more effective in the hands of someone light, fast agile and flexible so young and maybe female.

Due to this after graduation the decision based on the concept of if you cannot beat them join them was applied and I looked into how the form could be redesigned as a prop weapon emphasising features suited to this use and losing some or the cooking related ones like the scalpel holder.

The conclusion was that this would be too dangerous in the wrong hands for a kitchen knife so started to be redeveloped as a mock/play combat weapon or the template for a film prop.The form was enlarged and repurposed as the Praying Mantis LARP Live Action Role Play weapon system.

Method of Use as a Twin Hand to Hand Weapon System

Forward to 55 secs

Forward to 20 secs

Forward to 2 min 30 secs

Praying Mantis LARP Weapon System Redesign and Construction

- First printed out in line form then used to make card templates used to mark out where the Plastazote foam blanks were to be cut out.

- An internal structure was needed so the middle foam blank had slots cut out.

- The rods to make the internal structure needed to be parallel and precision yet I only possess basic tools like a simple pillar drill so special labels were designs, printed and applied to the 10mm tubes to enable correct insertion of the thinner cross-rods joining the handle / hilt to the blade section and to give it strength and rigidity.

- The thinner cross-rods needed to be level with the 10mm handle / hilt and blade tubes and to level with the foam so a novel use of plastic spoon handles was incorporated. All held together with glue gun glue which has some flex thus impact resistance. These were then sanded down and inserted with contact glue into the centre blanks.

- The internal foam surfaces were roughed up to aid glue adhesion.

- The rod tops had plastic (Margarine pot) plastic plates backed by Rip Stop nylon patches to prevent rods working their way through the foam if bent.

- When glued together the 3 layer blank was carved to shape with a Powerfile, taking into account the thumb dents and concave side for palms as well as the finger guard slot.

- The blade forms were then carved into place.

- Sanded smooth with some heat treatment as well, the form was painted in over 8 layers of latex mixed with acrylic paint.

- Finally griped were glued around the hilt.

Construction