Prop Tarantula Proposed

Further Development

Fur and Surface

Issues

A problem with the the spider at present is it looks plastic and typically spiders especially tarantulas tend to be fury. Adding for would give it a more alive, organic appearance and some roughening. Hopefully this would make it more realistic and intimidating.

This however should open up to issues like weather proofing, more fire risk, cleaning and attracting dust and dirt.

Possible Techniques

Methods to creates fur look could include:

- A flocking gun system that electrifies to surface coated in water proof glue then shoot out hairs that stick pointing out as opposed to flat. II cant afford this.

- Individual hair insertion: Problematic on a hard surface.

- Super glue outdoor brush hairs. Costly and would take a long time.

- Glued shredded wool.

- Modelling Moss.

- Fur Coats or Rugs.

- Any or the above attached to a hessian material shaped to form a skin tight coat with fur on the outside that could be taken off.

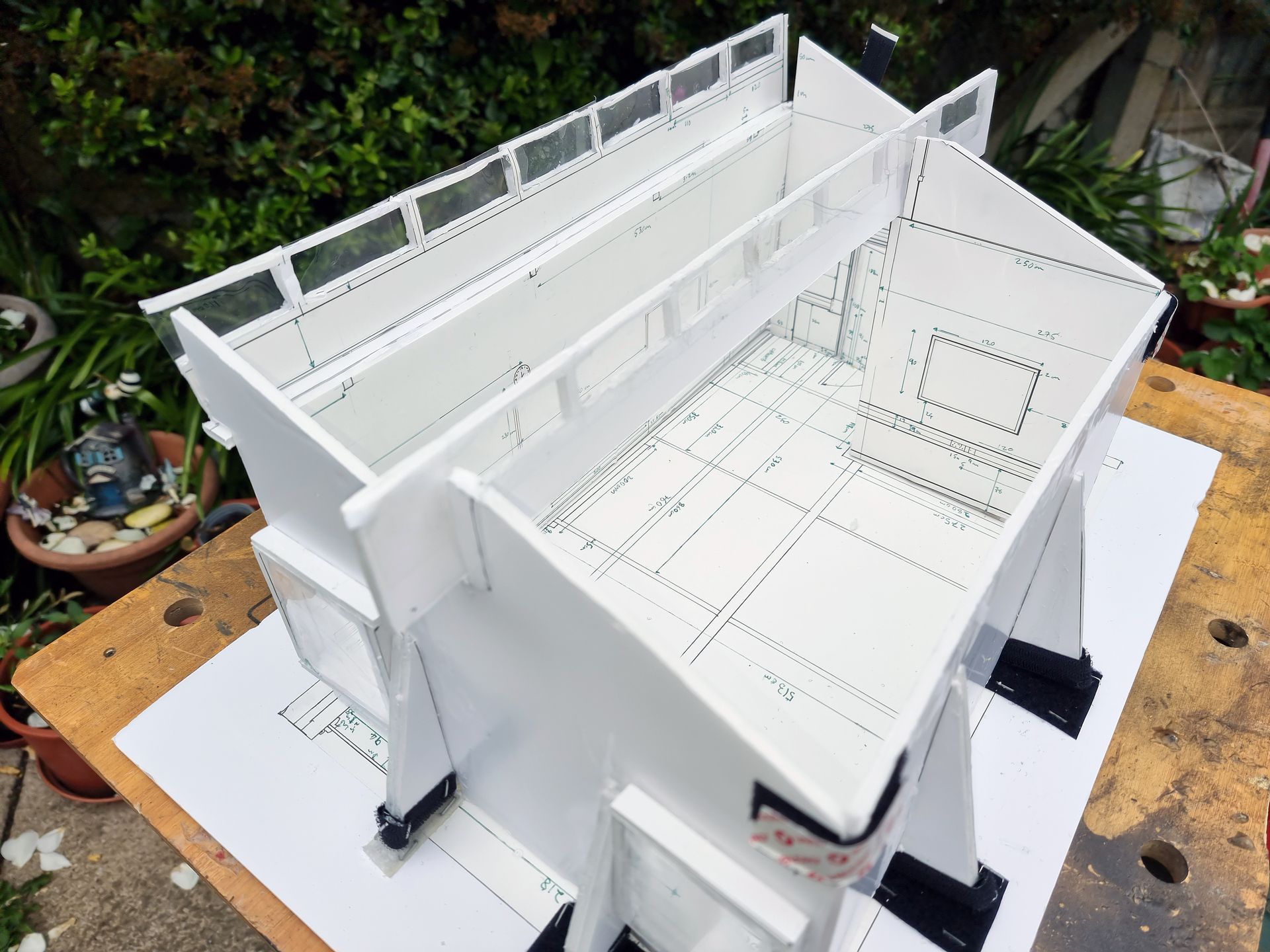

Proving Principle Prototyping Experiments

Following suggestions, experiments were carried out on wire brush shredded wool, Modelling moss and whilst in the shop had a look t bags of cedar leaves.

An analogue for the spider was made from a blank that had been filtered over and painted. A weather and water proof glue was tried by leaving in the shower for 20 minutes then dried. with no problems

All 3 materials on the plank analogue stayed stuck and did not flatten out or deteriorate other then the moss which has some colour washout.

The next attempt should be to use hessian or another material, that a fur system like the wool could be built up on that could fit the spider head and body but easy be removed.

Removable Coat

The advantages of a sewn up removeable coat are:

- It does not damage the prop spider itself other than maybe rot from trapped water minimising the repairs.

- Its is potentially washable.

- There can be more than one colour coat.

- The fur may attach better to the material.

- The coat could be used to hide things like connectingbuckles

Spider Title & Intro

Page

This was a double bed size prop Tarantula, originally intended as a cool Halloween front of house prop as well as portfolio piece to discuss project development.

Finished project page.

Spider Initial Research & PPP Testing

Spider Initial Research & PPP Testing

To start the project was looking into existing props and Halloween tableaus and how such a project could be done.

View More

Initial Proving Principle Prototyping & scale modelling.

Spider Development

Head

The main central part is the head to which all other parts are connected and would be the section to connect stands and load supports.

This involved the most substantial development and most restarts.

Spider

Development

Body

This had a similar basic structure to the head but a lot simpler. It does have its own issues and problems.

This had to be re-opened for upgrades to strengthen the connections to the head.

Spider

Development

Legs

Spider

Development

Legs

The legs required repeated and costly redesign and rebuilding building to try and build enough strength into them to be able to support the weight of the spider, as well as look realistic and bond the paint to them.

View More

Spider Development

Leg Connector

The system to connect the legs needed substantial improvement and iterations developing these connection components through CAD and rapid prototypng.

Further Development Head

Further planned developments & problem solving for the head.

The next staage here would be fur.

Further Development Body

Further planned developments & problem solving for the body.

This will need to be split into sections for storage that can be easily reassembled.

Further Development

Legs & Connectors

Further planned developments & problem solving for the legs, strengthening them to support the weight of the spider.

Further Development

Skin and Fur

Further Development

Skin and Fur

Plans to further develop the prop Tarantula and current unsolved problemsand issues

View More