Decimator Hybrid LARP Weapon System

Advanced Blade Tip Development

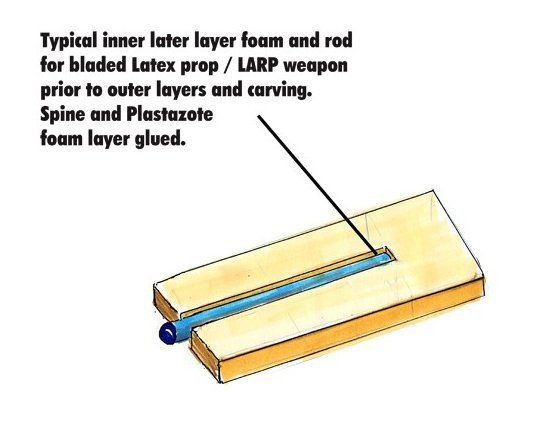

This was a concept car test bed for innovation ideas so what was looked at was ways to improve sections. In general one of the biggest problems with bladed Live Action Role Play (LARP) weapons such as swords and daggers is that the blade tips break easy exposing the reinforcing rod / tube.

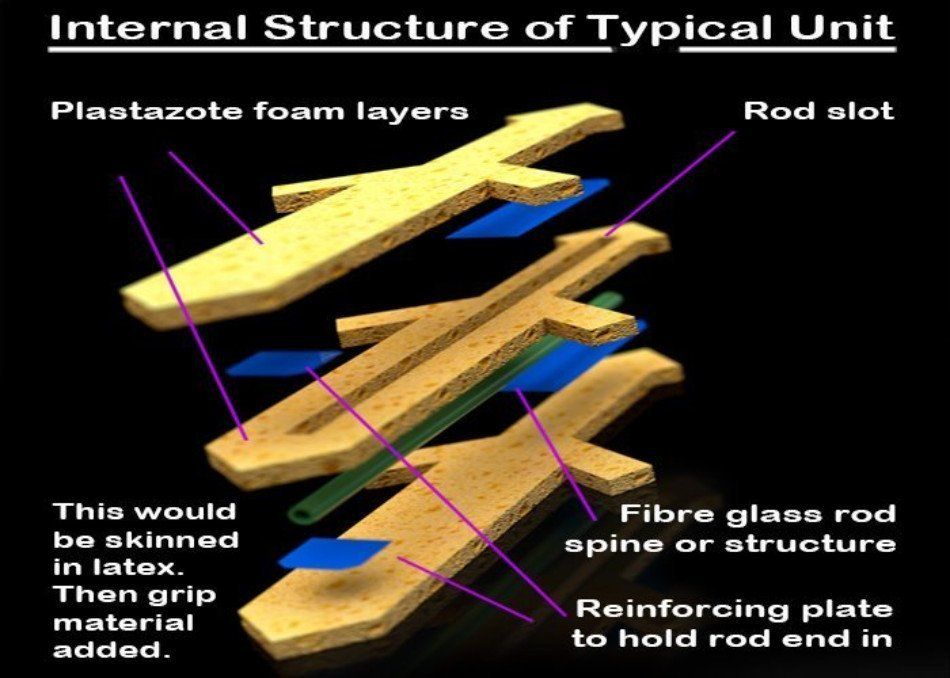

This is as normally construction would be 3 layers of Plastazote foam, the rod in the middle layer. The problem is that for safety reasons the rod cannot go all the way tip to tip. This is because when jabbing someone it would hurt, as there would be no cushioning between the rod end and the person being jabbed. Thus the rules are for about 5 cm of foam at the end. As the foam is soft and stretchy, it tears as the rod point stabs through thinned foam. The foam absorbs over a wide area not so much over a small focal point.

This is as normally construction would be 3 layers of Plastazote foam, the rod in the middle layer. The problem is that for safety reasons the rod cannot go all the way tip to tip. This is because when jabbing someone it would hurt, as there would be no cushioning between the rod end and the person being jabbed. Thus the rules are for about 5 cm of foam at the end. As the foam is soft and stretchy, it tears as the rod point stabs through thinned foam. The foam absorbs over a wide area not so much over a small focal point.

The most basic way I knew to reinforce the area where the rod ends in the blade tip was to stick plastic plates over the ends

(Cut from margarine tubs). The like armour spreads the force over a ride area instead of a small point so it’s the hole plate pushing up into the foam when someone is stabbed and the tip compresses and bends.

(Cut from margarine tubs). The like armour spreads the force over a ride area instead of a small point so it’s the hole plate pushing up into the foam when someone is stabbed and the tip compresses and bends.

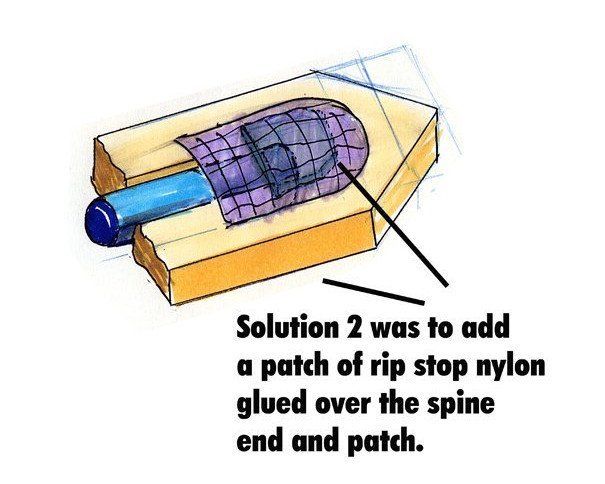

Further still was the idea to sewn with fishing line through both sides of rip stop nylon and foam. This action prevents the rod pushing the plate and patch away from the foam breaking the glue bonds. As sewn through to the opposite layer this opposite layer hold the flexible patch to the foam as you would have to drive the other side reinforcement through all the layers. It counter balances things. It’s like you having holds in a door and holding someone’s arms through the holes then trying to pull them though the door they hold you in place as opposed to just gluing your clothes to said door and trying to pull away.

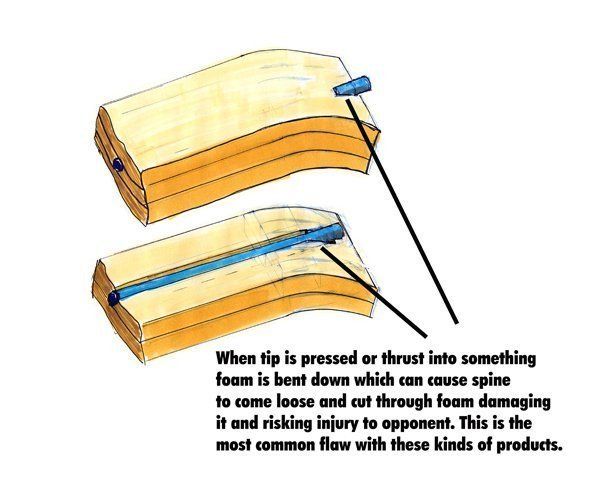

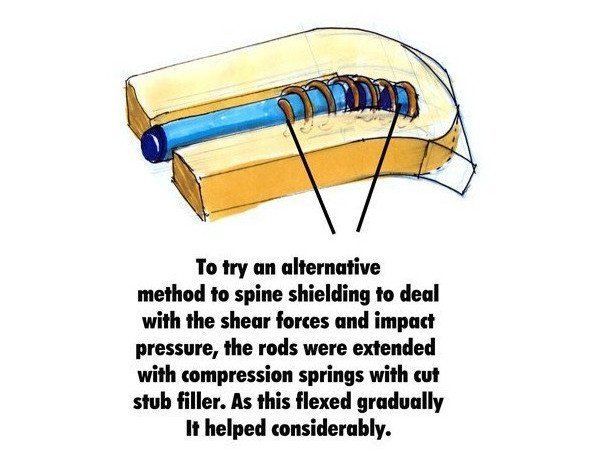

All of this still works around the issue of a stress point at the end of the rod where suddenly there is a dead end with little holding the end of the rod to the layer of foam just a round centimetre. This creates shear forces much like how scissors work. One layer goes up the other down.

What was needed was a way to see the rod gradually bending / finishing in a manner that is soft to the person being jabbed and that springs back to shape, or more simply make the end of the rod stiff but bendy and elastic. This way the rod does not pierce through the foam pulled thin over the tip.

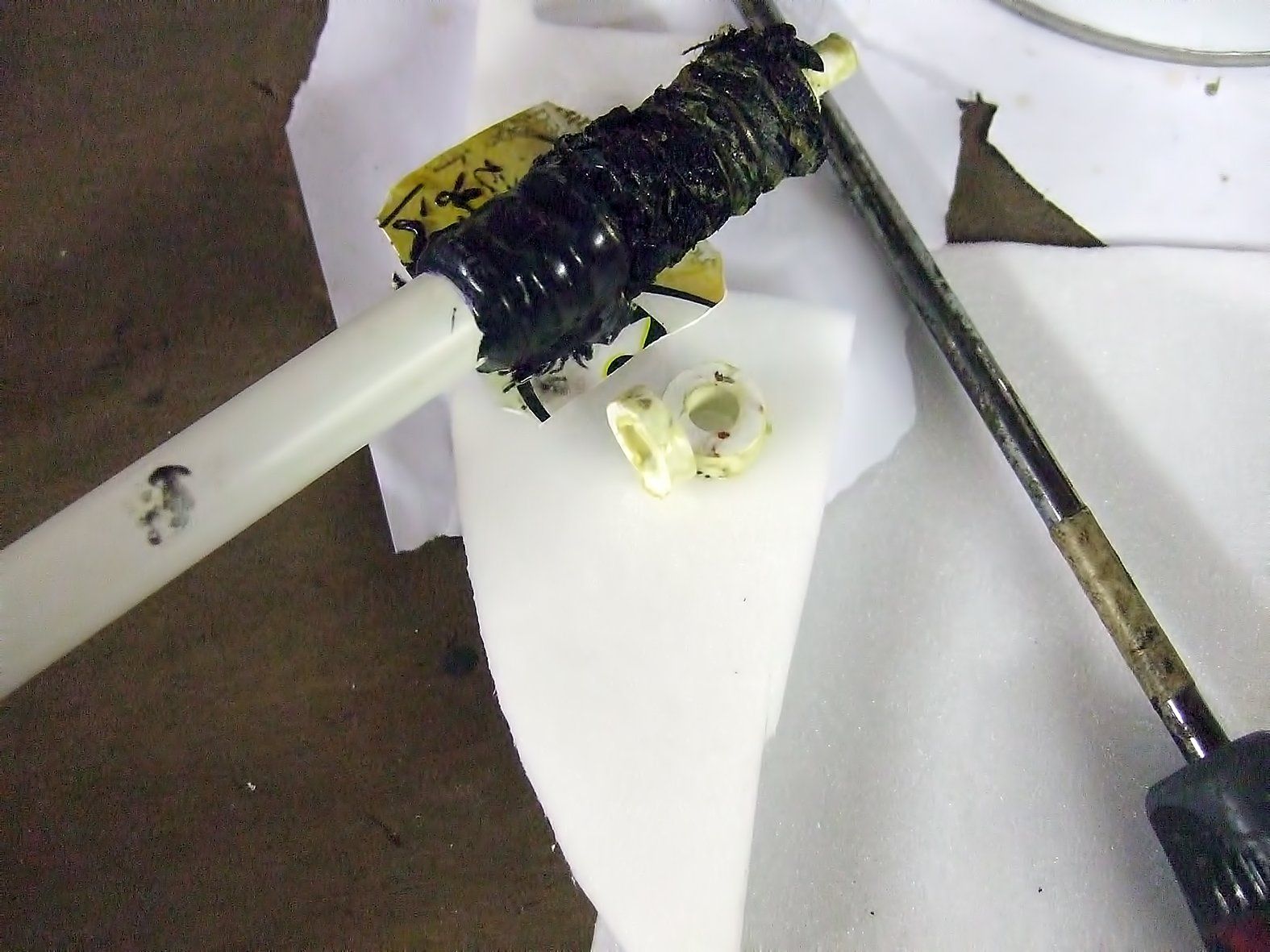

The solution here was to attach a spring to the end of the rod.

The problem then is that springs being wire, do not have much to stick to the foam being hollow. Filling the spring with something solid defeats the purpose of the spring. Filling the spring with segments, some flexible filler and glue such as that used on neoprene foam wet suits, in between the spring rings stretches and bends the rod whilst maintaining a flexible outer skin. This enables adhesion between the solid shaft, flexible rod tip and foam layers granting a stiff blade but flexible compressible tip that does not stress the tip.

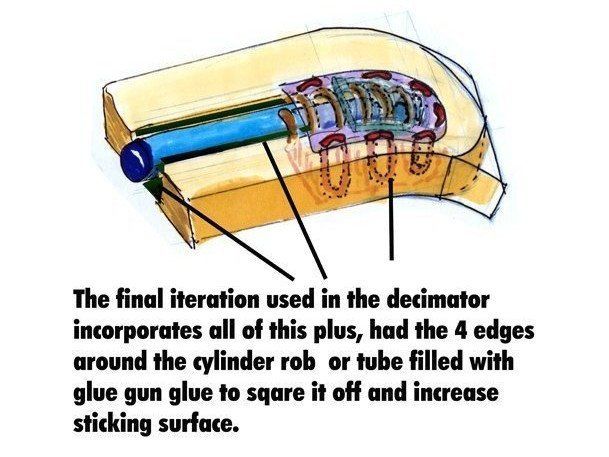

The only thing to do next was to throw in all the other features such as the plates and reinforced material cover to get super tough, reinforced springy flexible tips, ideal for jabbing an opponent without damaging them or the blade tip.

Full Design Process Report

Please click on the image for the full detailed design process development report for this project. The bottons cover the various elements that went into the design of the hybrid, the design decisions and project development

This was far more complex than any of the LARP weapons done before and many of the other projects here.