Domiciles Gameshow Concept Bid Miniature Set Model

Construction Phase

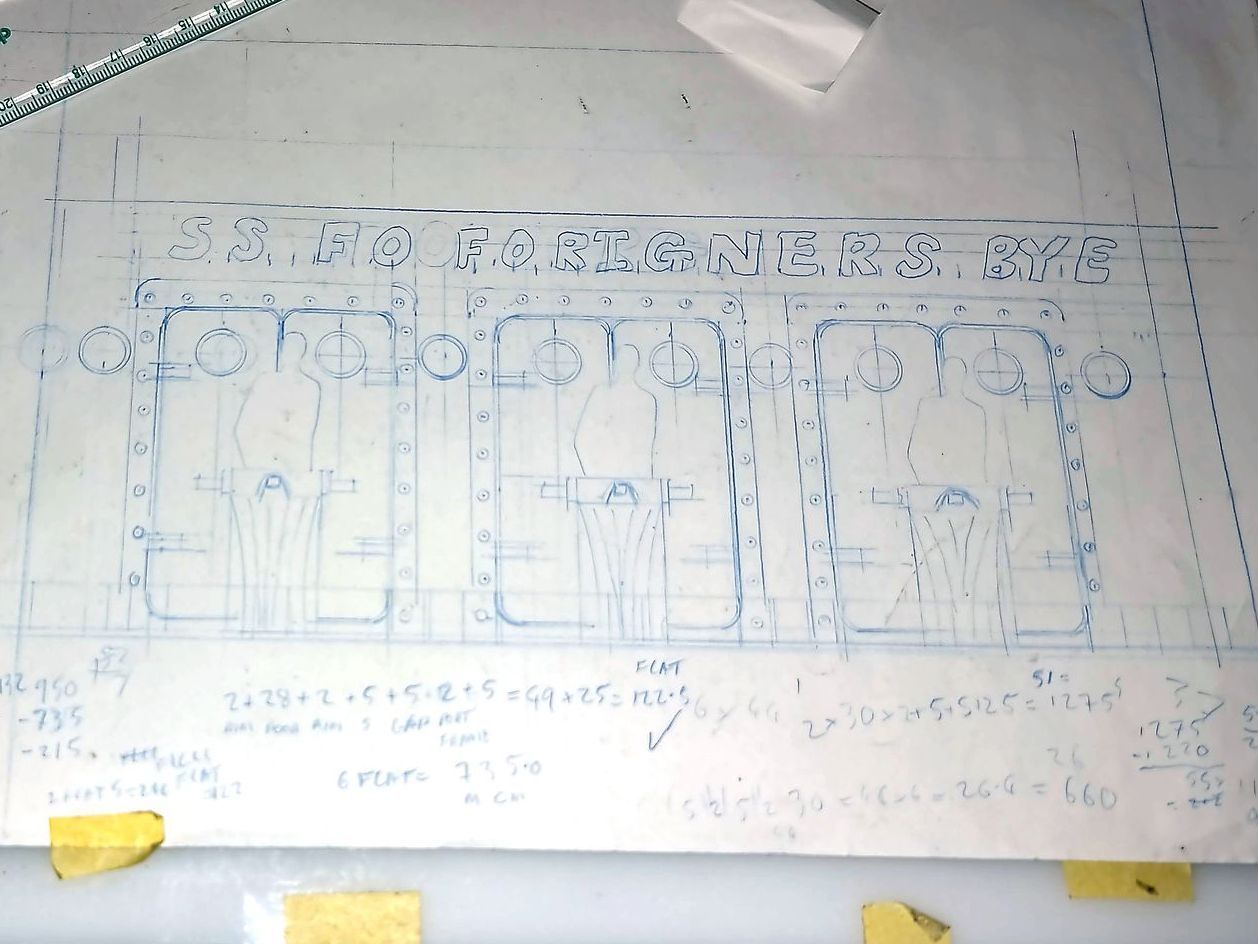

Ship Construction - Initial Ship Doorway Construction

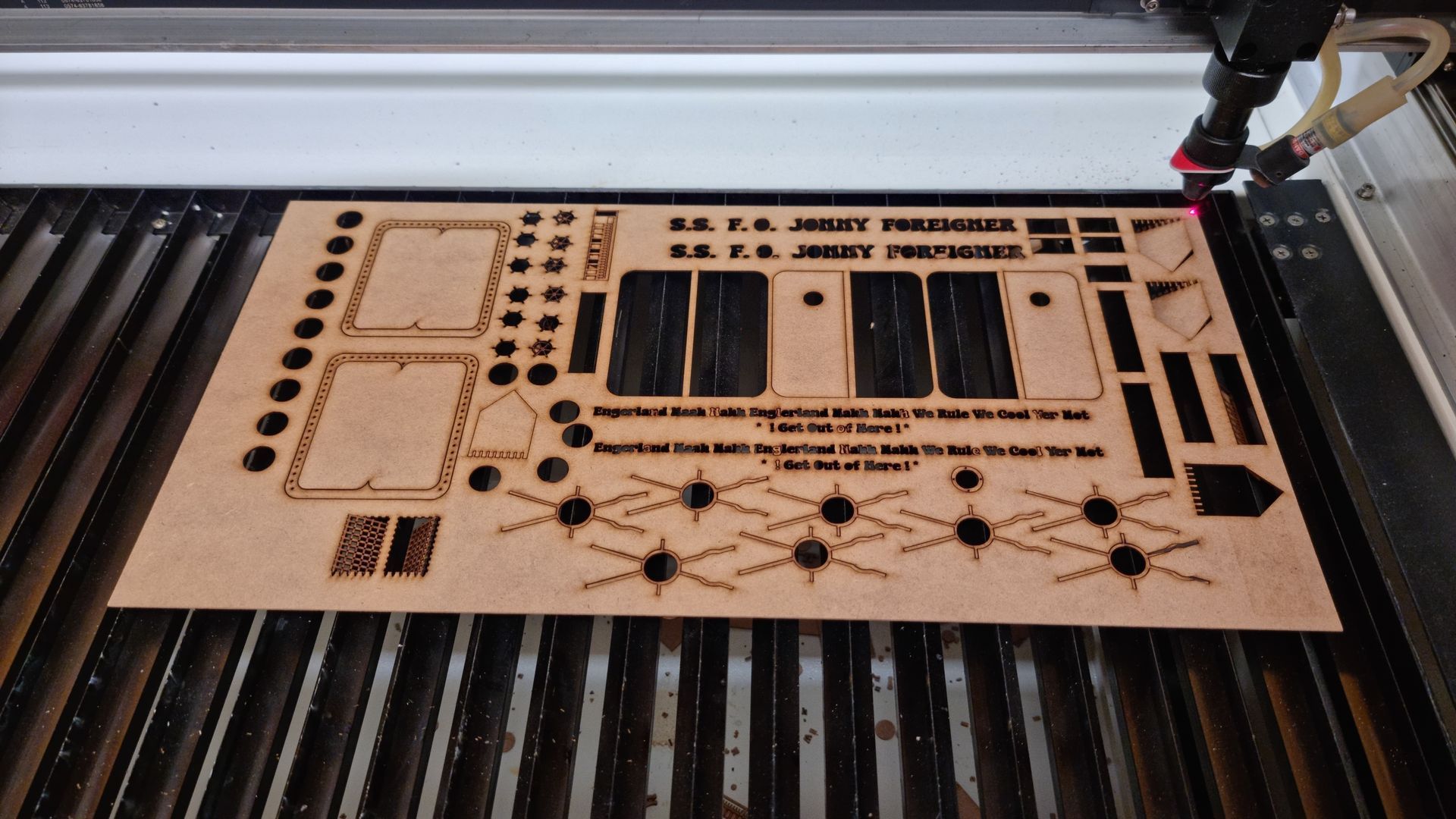

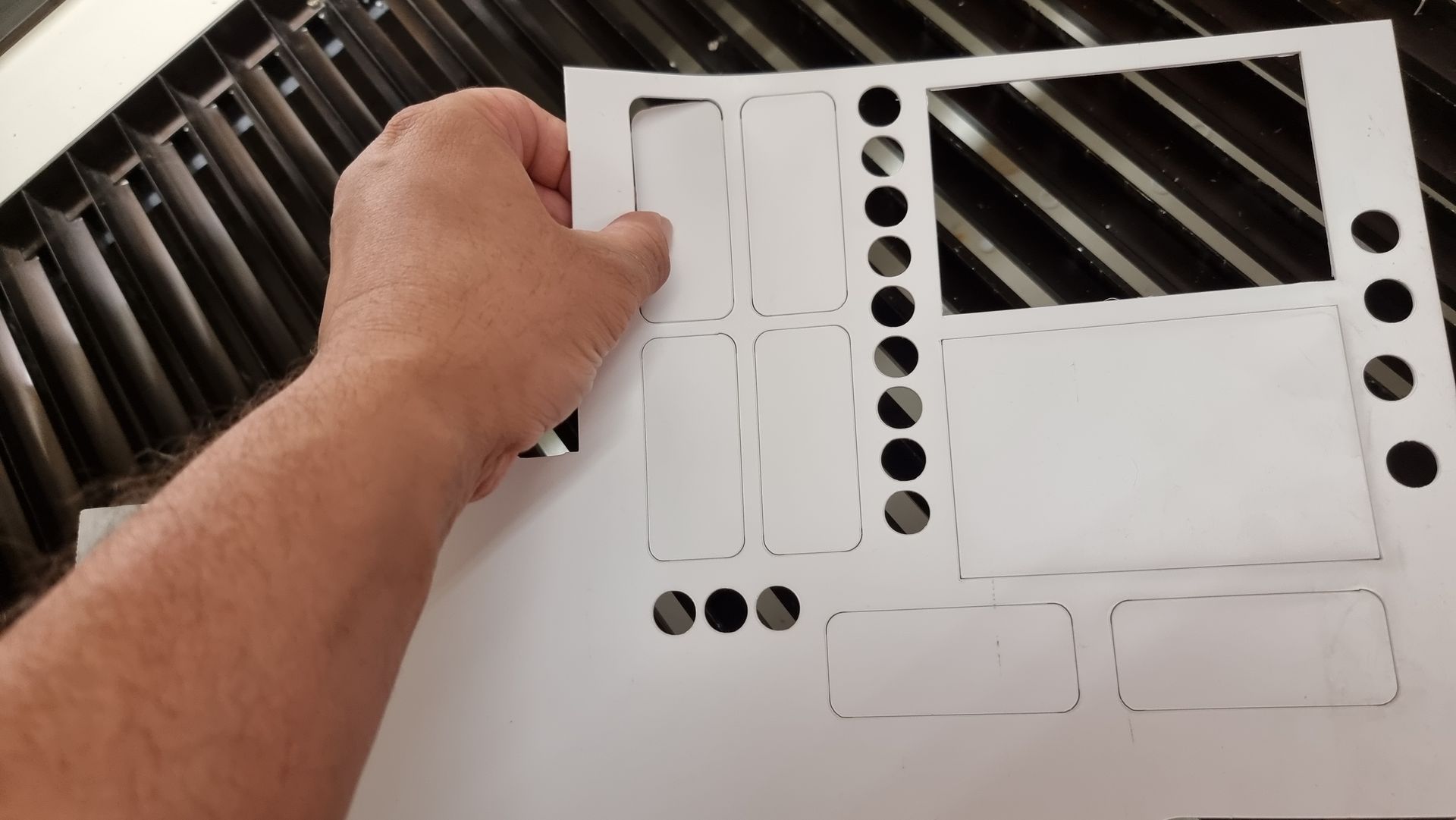

The ship surfaces where laser cut from the usual Kapa or Palight foam board.

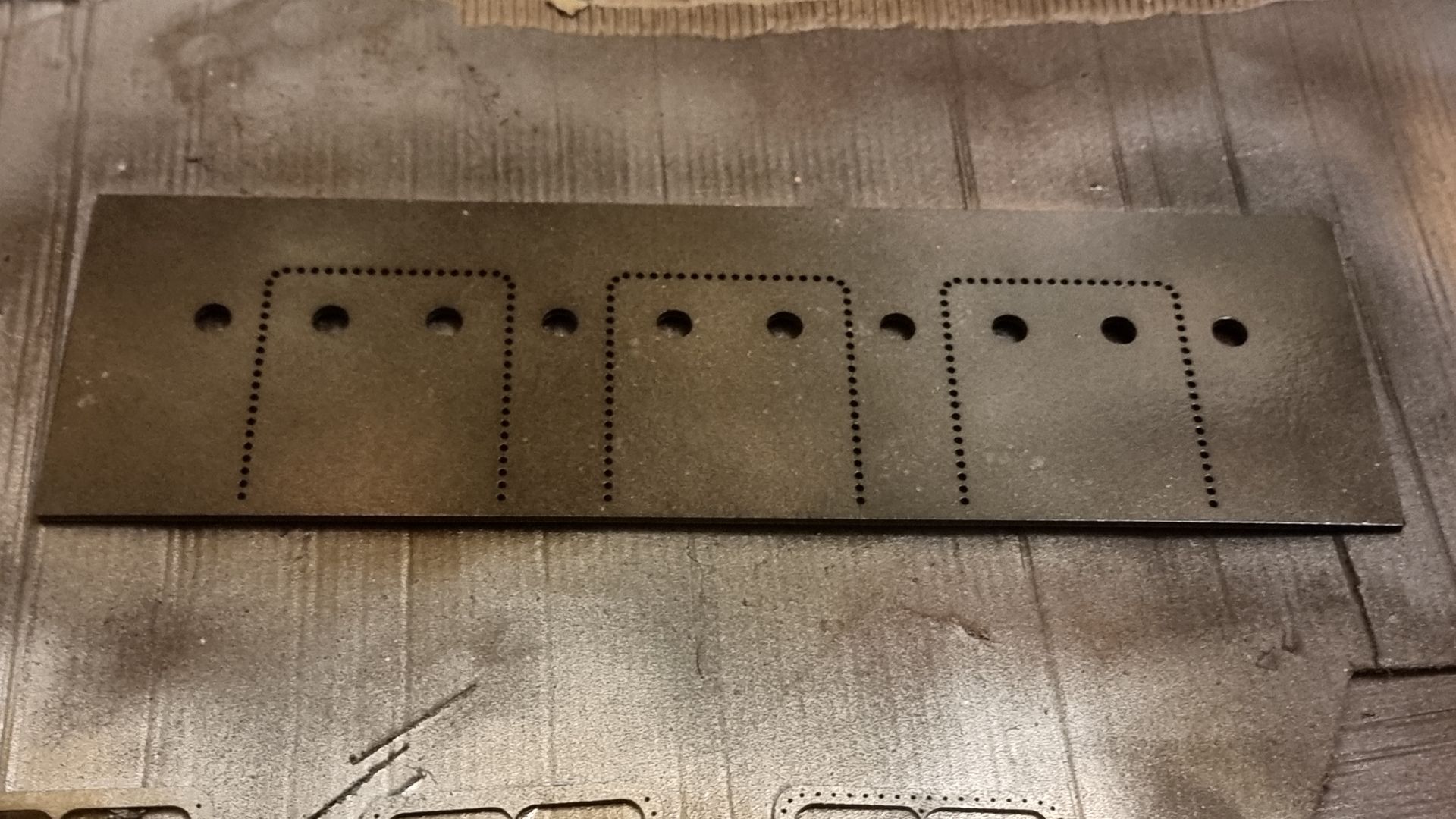

Next the door surrounds were laser cut from 1 or half mm MDF as plastic that thin would be subject to warping I was told.

The inner door was 1 and 1.5mm polystyrene I believe to give a more metallic finish and depth whilst the rear was still MDF.

If the laser was too not there was the danger of indenting in the edge rather than a straight vertical cut.

These were spray painted in primer them metallics mixing chrome and steel, some black and copper or gold to get a good shade and mic with some dirty down sprays.

The different layers like door frames and inner and outer door sections were done in different shades.

The ship surface whilst mainly black has light spray mixes of metallics to metallize the finish and mess it up.

Several of the delicate door undersurface mechanics needed light repairs with superglue.

I also started to look at glued sand with rust dirty down spray to show rust on the doors.

The inside of the portholes as meant to be black acrylic but had to accept dark brown to give a glass window finish.

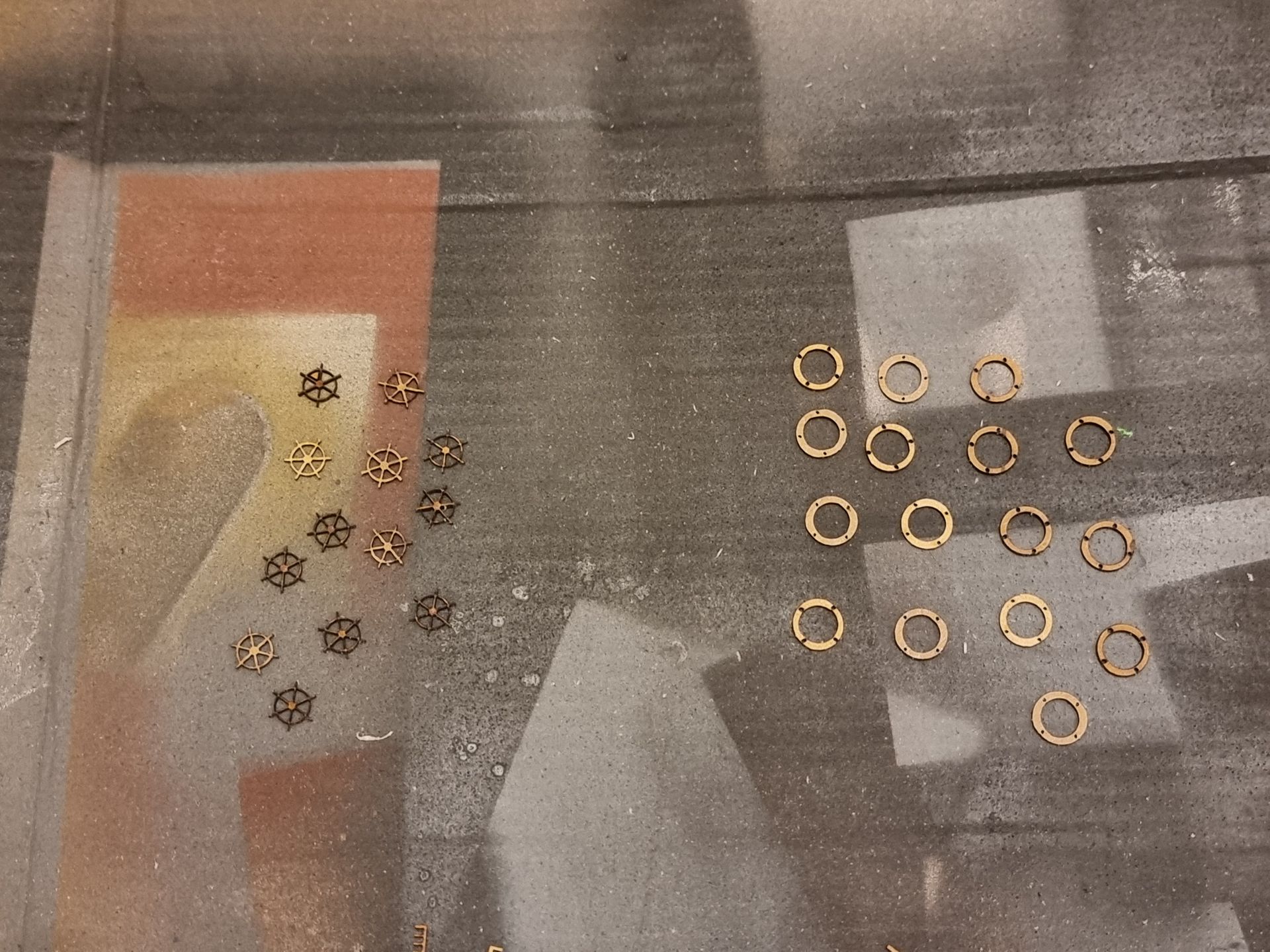

Marine Pressure Door Hand Crank Wheels and Portholes

The door locking wheels are hand cranks, used on pressure doors to evenly pressurize door seals and the door mechanics strips used to indelicate internal workers

The could only be done with precision laser cutting and were 0.5mm thick MDF to appear very thin and delicate and too thin to be made from plastic due to the laser heat.

The door handle or locking wheels and the door mechanics strips used to display internal mechanical were .5mm MDF.

They needed to appear very thin and delicate. This woudl have been difficult to laser out of plastic as likly to melt and warp wit the laser heat.

I had the wheels superglued to bronze beads to site them away from the doors and give them a pivot to look more metallic in copper.

As these were super delicate there were lots of spares made.

The portholes were also MDF as previous plastic attempts had warped. I also look into making portholes with 10 cm ringlets intended for clothes, flags and connecting strong points in materialsm but then would have not bolt holes on them.

As the doors where smooth shiny plastic they needed to be scratched up and roughened to aid adhesion.